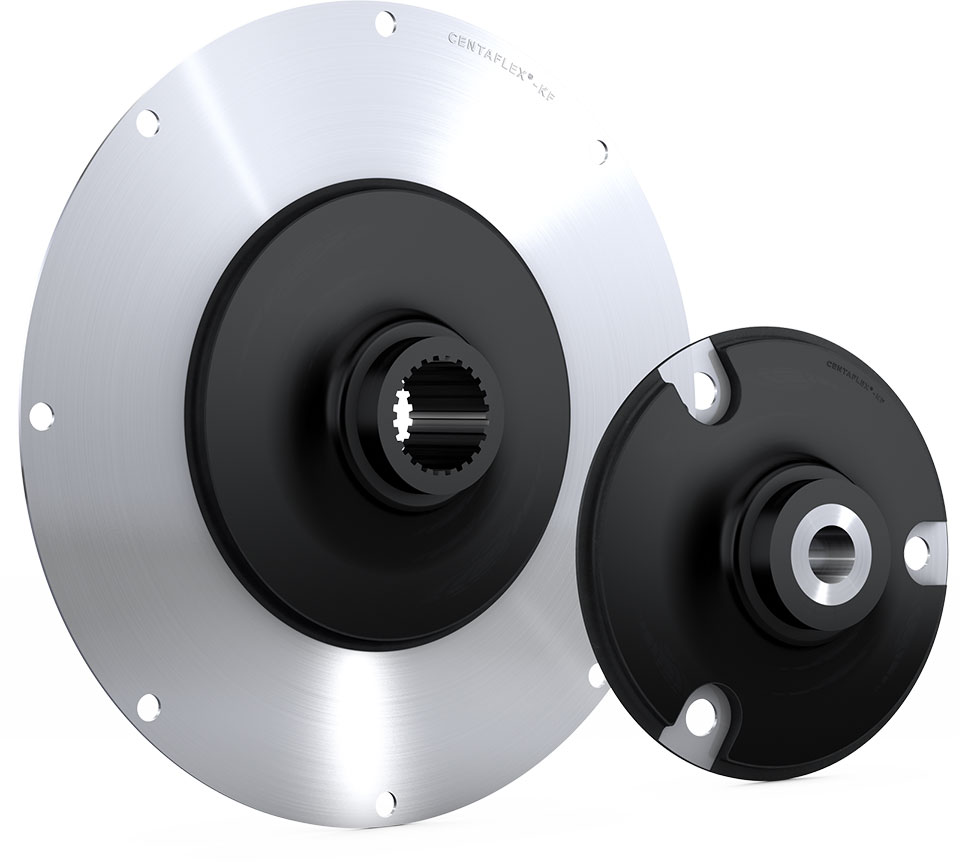

The CENTAFLEX-KF is a cost-efficient, torsionally stiff, lightweight one-piece coupling ideally suited for diesel hydraulic drives with splined input shafts. This coupling is an excellent choice for applications where compensation of radial misalignments of up to 0.7 mm is required. The CENTAFLEX-KF offers temperature resistance up to a short-termed maximum of 120°C (250°F) to address the temperature issues found in sealed machinery. With a high torsional stiffness for subcritical speed operation, the CENTAFLEX-KF features an axially short build, an advantage in flywheel connections. Easy adaptations are available for many flywheel and splined hub connections to ensure the flexibility of your drive. The CENTAFLEX-KF includes a laser machined adapter plate for flywheel connections, a secondary flange of reinforced plastic, and a thin, vulcanized layer of temperature-resistant elastomer. Easy-to-assemble blind mount design keeps assembly costs low.