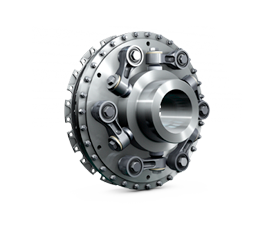

Designed for soft mounted drive concepts, the CENTAX-SEC-N/NL series is another highly-engineered product in the CENTAX-SEC portfolio. The ring element features high torsional and radial flexibility, along with flexibility in axial and angular directions. Designed with amply-dimensioned secondary inertia to help eliminate torque reversals/gear chatter, high torsional flexibility, and optional fail-safe device, the CENTAX-SEC N/NL are highly adaptable to application torsional requirements by using components with varying degrees of shore hardness. The CENTAX-SEC-N/NL damps torsional vibrations and compensate considerable axial, radial, and angular misalignments. Like other products in the CENTAX-SEC portfolio, the SEC-N/NL are effectively ventilated for a high allowable energy loss. Available with flywheel connections according to SAE, the CENTAX-SEC-N/NL require minimal mounting effort and provide fast, customized solutions.